What’s taking so long?

Supply chain delays put damper on shipping times

When even one part of the supply chain is delayed, such as the manufacturing or transportation of an item, the whole chain is affected.

Ever since the beginning of the COVID-19 pandemic, shipping delays have been a common occurrence. Unstocked shelves have not been a rare sighting in stores. There is one major cause for all of these empty shelves and long waits for buyer’s purchases: supply chain shortages.

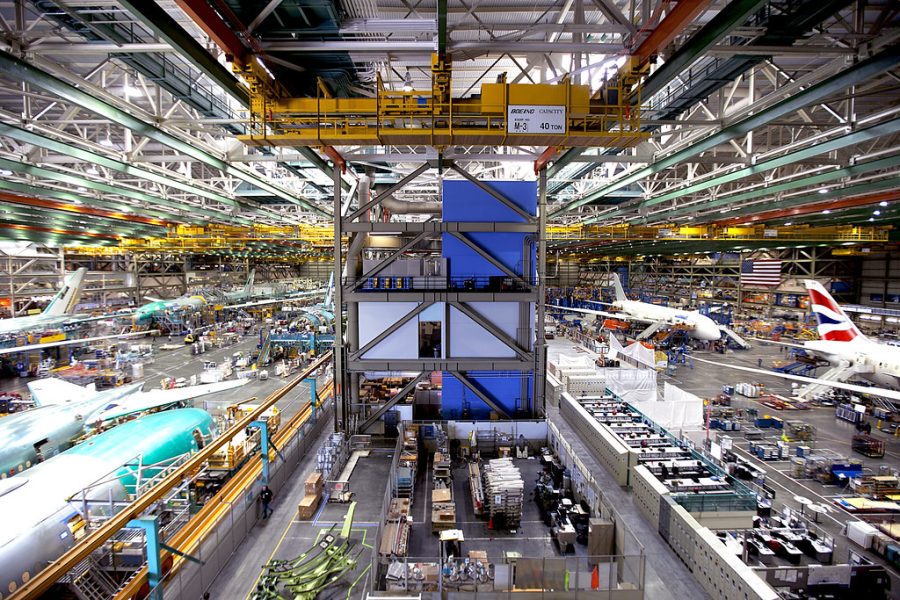

Supply chains consist of transporting and developing items from the time they are just raw materials until they are finished products. Raw materials are sent to a supplier, who then delivers the materials to a manufacturer. The manufacturer assembles the product, and they hand over the items to a deliverer. Once the deliverer reaches its destination, the retailer receives the product to sell to customers. When even one part of the supply chain becomes delayed, the whole chain is thrown off. Usually, there is a setback in the manufacturing area of the chain. Millions of factories have lost a large portion of their workers due to the COVID-19 pandemic.

Not only have factory workers become sparse, though, most aspects of the chain are also short-staffed. There has been a scarcity of truck drivers, and with how many online orders are placed every day, the demand is hard to keep up with. Also, there has been a decrease in employees, in general, all over the country. According to a survey led by CNBC News, half of the surveyed people have been dissatisfied with their jobs due to labor shortages, which are causing extra stress on those who are working.

Many local businesses have been facing challenges due to supply chain delays, as well.

“There is a shortage in seamstresses which is causing delays in getting the costumes produced and delivered as planned, so they keep getting pushed out,” a dance teacher at Star-Styled Dance Center in Cranberry, Pa., said.

The studio has had trouble lately getting new costumes in for their competitions, so they had to reuse their outfits from past years. A shortage of seamstresses caused many push backs in the production of the costumes.

Additionally, restaurants have been having trouble getting their supplies and food into their facilities. Bill and Theresa Phillips, owners of Marbulls in New Brighton, Pa., have been facing some of the delays and shortages in the restaurant business.

“Last week, potatoes went up more than $20 per box because of an issue with the transportation, so instead of the food-service company covering the cost, they passed it onto the individual businesses,” Bill Phillips said.

They were told that the cost was over $30,000 more than the standard transport fee. The restaurant owners also said that each week when they place their orders, they come across more and more items listed as ‘out of stock.’

“It’s only going to get worse, and the prices are just going to continue to rise,” Bill Phillips said.

Going forward, business owners and customers alike hope to see an end to the supply chain shortage. Faster shipping and in-stock items would be appreciated by all.